The first clue we had that our water tank baffles were giving issues was having things go “bump” in the night. We had a mysterious knocking in the forward starboard side that we just couldn’t find – I initially thought it would be a stray can of beer or bottle of rum but no matter how hard I looked I couldn’t find anything that was going “bump”. We looked inside and out but the bump continued, months passed… We were also seeing glass fibre strands and gel coat chips in the water strainers - at the time I thought it was probably debris from the original build.

When checking the water tank by chance a boat went past and the wake caused the bump and I saw the baffle move – it had become detached along its aft edge. There are three baffles in the tank but you can really only see the first one and even that is hard.

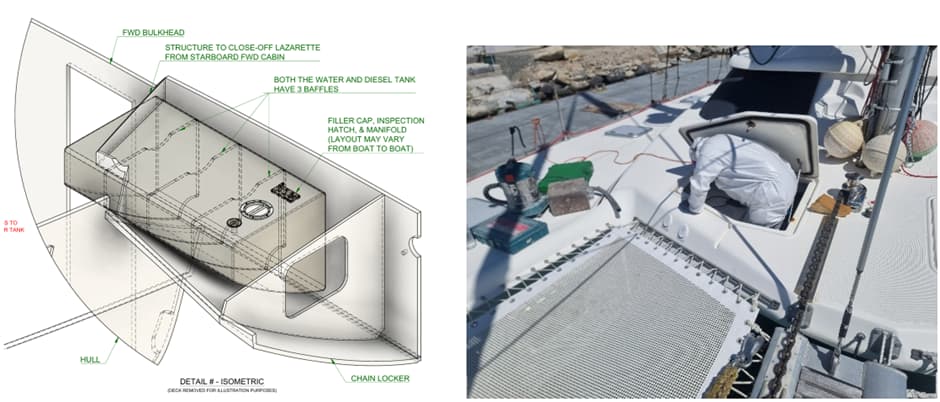

After consultation with KYC they provided a repair procedure and some great diagrams to help us understand what needed to be done. We found a GRP specialist yard to effect the repair, the correct materials were sourced and shipped in (food grade resins and flow coat), the work dock was booked.

There is no easy way to access the baffles, it’s impossible to work through the round inspection hatch.

So following the process we had been given, the angle grinder came out and the top of the tank was cut out.

Both of the main baffles were partially detached – so the tank was dried, cleaned ground back – and the baffles re-bonded and fixed in place with GRP tape and resin. After it had all been allowed to cure it was re-painted with food grade flow coat.

The top of the tank was then reattached with tape and resin then flow coated to match. We took the opportunity to add a second inspection hatch so we can now access the 2nd compartment of the tank as well as the first.

The yard “Raiatea Marine” (in French Polynesia) who normally build the local tourist boats did a fantastic job. They even gave us the best job report at the end of the works that we have had from any marine supplier anywhere in the world!

Thanks must also go to KYC for being very supportive and helping us with the process to effect this repair.